SINCE 1850

DR. LUDWIG GMBH

A MODERN COMPANY WITH TRADITION

175 years of Thonwerke Ludwig GmbH & Co. KG

Video greeting from Prime Minister Alexander Schweitzer to mark the anniversary

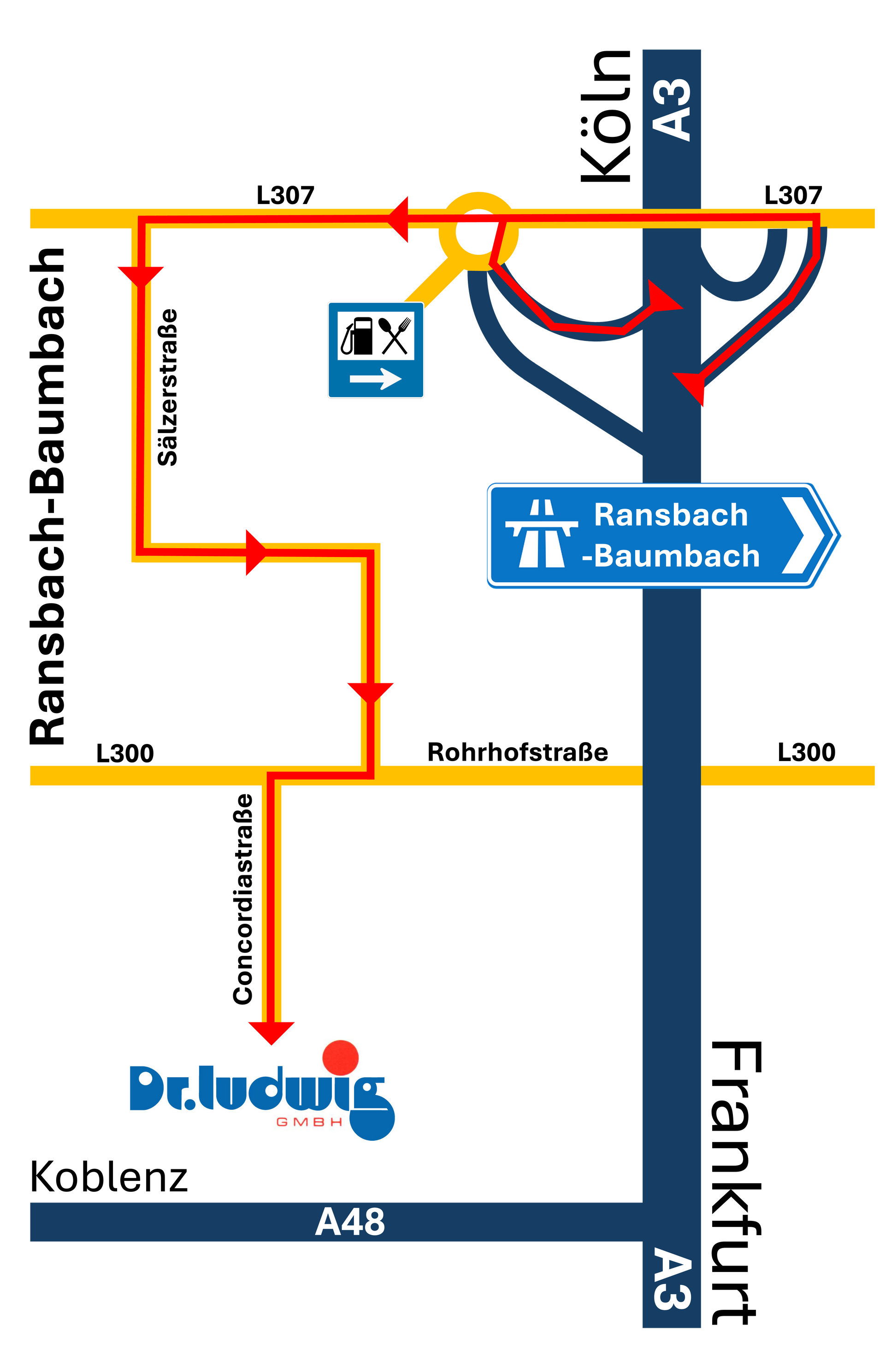

Concordiastraße

D-56235 Ransbach Baumbach

Loading times

Monday to Friday 6:30 to 14:30

27.06.2025 Company anniversary:

175 years of Thonwerke Ludwig GmbH & Co. KG

17.06.2024 Sustainability:

Commissioning of a photovoltaic system on a 1,550 m2 roof with a capacity of 250 kWp. The system will cover approximately one-third of our annual energy needs.

Archive of Dr. Ludwig GmbH

This content will follow shortly

Quality meets innovation: Our company for refractory products

Dr. Ludwig GmbH was founded in 1973 as a subsidiary of Thonwerke Ludwig GmbH & Co. KG. Dr. Ludwig GmbH is a medium-sized family business managed by its managing director, Friederike Winter (Dipl. Business Administration), the sixth generation of the Ludwig family.

The innovative team of 30 employees is highly motivated to continue the "Werk Concordia" site beyond the company's 175-year history. The company's expertise focuses primarily on the production of unshaped refractory masses, mortars, and concretes for the steel industry, foundries, and stove construction. Dr. Ludwig GmbH operates in accordance with the regulations of DIN EN ISO 9001 and strives to fully meet customer requirements.

The company continuously faces the challenges of the market, with social competence, sustainability, economic success and forward-looking environmental protection forming the basis for responsible business practices.

Our Mission

For generations, we have been producing high-quality refractory mixtures and regrinds that combine durability, innovation, and sustainability. Our actions are shaped by tradition, progressive thinking, and the trust of our customers and employees.

Our vision

Our vision is to be valued as a tradition-conscious family business for our safe and reliable refractory products. We strive to build and maintain long-term, trusting partnerships with our customers and employees.

Our services at a glance

grinder

Precise hard crushing – powerful and flexible

Our hard crushing plant relies on modern technology: three primary crushers, two smooth roller mills, two Mogensen sizers and a powerful dryer ensure efficient processing of a wide variety of materials – even those with the highest hardness levels (up to Mohs 9).

From coarse lumps to fine grains: Through multi-stage crushing and screening processes, we achieve precise grain distributions – standard grain sizes such as 0–1, 1–3, 3–6 mm, or customized customer requirements are easily possible. Wet material is pre-dried to 0.2% residual moisture, and a magnetic separator ensures low-iron quality.

Whether for our own refractory masses, pure contract grinding or contract screening – we deliver flexibly in big bags, 10 or 25 kg sacks or loose in silo trucks.

Do you need precise shredding at the highest level?

Talk to us – we will prepare your material exactly according to your wishes!

Precision. Efficiency. Flexibility.

mixed house

Flexible mixing at the highest level

Our mixing facility offers maximum flexibility and quality. Four powerful mixers (Hess and Eirich systems) enable the processing of a wide variety of raw materials from silos, big bags, or bagged goods. Recipe changes are possible within 30 minutes.

We deliver customized solutions based on your needs. In addition to our own products, we also undertake contract blending – with absolute focus on quality and customer protection.

Are you looking for a reliable mixing solution?

Contact us – we will find the right solution for your material!

Act sustainably – recycle refractory materials

Sustainability is a lived practice for us. We recycle used refractory materials that are no longer suitable for production and return them to the material cycle through a high-quality processing process.

Secondary materials are used to create new, usable products that easily meet the demands of industry. This way, we avoid waste, conserve natural resources, and reduce the need for primary raw materials.

A win for our customers and for the environment.

Do you want to recycle fireproof materials sustainably?

Contact us – we take care of take-back, recycling and reprocessing.

Examples of recyclable refractory products (purity of type must be ensured):

| Used fireclay | 27% – 40% Al2O3 |

|---|---|

| Insulator porcelain | 35% – 50% Al2O3 |

| Sillimanite / Andalusite | 60% – 65% Al2O3 |

| Bauxitregenerate | up to 85% Al2O3 |

| Corundum- / Tabular regenerated | up to 90% Al2O3 |

| Fused cast material e.g. Corhart Zac | 33% ZRO2 |

We also do contract grinding – if required low iron – for recycling material, such as:

| Silicon carbide | 50 % – 99 % SIC |

|---|---|

| Prefabricated building reclaimed | (max. edge length 800mm) |

All types of aluminosilicates except basic materials.

Storage with a system – safe, flexible, efficient

On our 70,000 m² production site, we offer optimal conditions for storing raw materials and finished products. We store up to 30,000 tons of material in 52 largely covered storage bays – for our own use or as reliable interim storage for our customers.

Modern warehouses with a current capacity of 2,500 tons – expandable to 7,500 tons – are available for finished products. Four STILL electric forklifts ensure smooth and rapid handling.

Our wheel loaders (Caterpillar 950 M & 926 M) ensure fast loading of production facilities or material loading.

Do you need space for your raw materials or finished products?

We store your goods – flexibly, securely and according to your needs.

Talk to us!

Filling of the clay pit “Gottesgabe”

Our clay pit is conveniently located on the L 303 between Ebernhahn and Siershahn (Westerwaldkreis) and is accessible year-round via paved roads. It has been in use since the late 19th century and is now operated by two companies. The Ludwig company currently has an approved backfill volume of approximately 300,000 m³.

Backfill material is accepted by our subcontractor TOKI (Holler), represented by Mr. Thomas Kilian, Tel. 02602 / 4187. He is your contact for delivery, logistics, and pricing.

Backfilling will be carried out in accordance with the partial closure operating plan, approved on March 8, 2002, by the State Office for Geology and Mining (Ref.: To 1-G-20/00-7). Only materials with LAGA classification values of Z 1.1 or Z 1.2 are permitted. For delivery quantities up to 1,000 m³ per project, a clearance certificate from the district administration is sufficient. For larger quantities, a LAGA-compliant analysis (eluate and solids) by the client is required.

Retention samples are taken from each delivery and stored for a defined period of time. After backfilling is complete, the site is recultivated according to the specifications of the State Office for Geology and Mining.

Ton

Reliable sound supply – today and in the future

Even if our own clay reserves are running low, we ensure a continuous supply of a wide variety of clay types thanks to long-term supply contracts with selected partners – reliably and at competitive conditions.

Corporate policy

The management of Dr. Ludwig GmbH has established the following quality policy:

The market success of our refractory products is closely linked to their quality and is directly related to the effort to fully meet customer requirements and the needs of interested parties.

Our customers' satisfaction is the guiding principle of our actions. Our collaboration should be based on partnership, long-term relationships, and trust.

It should not be limited to standard solutions, but also include special products with the associated technical services tailored to customer needs. Such solutions should be innovative and cost-effective for both parties. Internal and external issues, as well as risks and opportunities, are continuously analyzed and evaluated.

Whether the customer receives a service, a standard product, a special product or a system solution from us, the promised properties must always be fulfilled.

We can only achieve our high quality standards with a qualified team of employees. We demand and encourage responsible, independent, and professional action.

All members of our company are encouraged to participate in the continuous improvement process through initiative and teamwork for the benefit of our customers, partners and our company.

The focus of our activities is error prevention, not error correction. Through preventative measures, we produce quality from the very beginning!

This principle and the requirements of the newly introduced standard DIN EN ISO 9001:2015 are all components of the management task and the corporate strategy and are followed at all decision-making levels of the company.

Code of Conduct for suppliers

Partner

Address

Dr. Ludwig GmbH

Werk Concordia

Concordiastraße

D-56235 Ransbach-Baumbach

info@dr-ludwig-gmbh.de

Tel. 49 (0) 2623 8001 0

Management / Purchasing:

Friederike Winter

winter@dr-ludwig-gmbh.de

Tel. 49 (0) 2623 8001 121

Operations Manager:

Axel Weimer

weimer@dr-ludwig-gmbh.de

Tel. 49 (0) 2623 8001 40

HR / Purchasing:

Jana Fritzsche

fritzsche@dr-ludwig-gmbh.de

einkauf@dr-ludwig-gmbh.de

Tel. 49 (0) 2623 8001 45

Sales / Internal Service:

Frank Groß

gross@dr-ludwig-gmbh.de

Tel. 49 (0) 2623 8001 50

Dispatch:

Johannes Hummrich

waage@dr-ludwig-gmbh.de

Tel. 49 (0) 2623 8001 19